Operating a company that works in the print industry can be difficult to, especially without the right equipment to back you up.

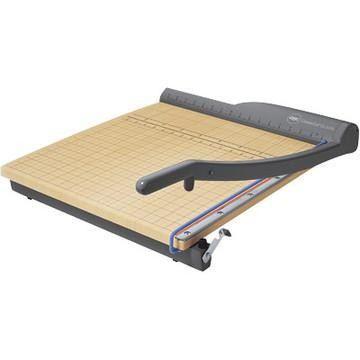

That's why, as faithful as it might be, your old manual paper cutter might be holding you back.

Join us, today, as we take a closer look at how, why, and when you should consider replacing your manual cutter unit with a newer unit and start cutting better.

Your Needs Are Outweighing Your Capabilities

Business needs can change quickly, depending on which projects you take on.

Paper is a resource you'll need to manage carefully or processing it can get out of your control. If you've noticed your paper cutting getting to a point where you aren't cutting enough paper to meet your deadlines, the writing may be on the wall.

Keep in mind you don't need to literally cut paper all day and not have enough work hours to possibly get all of it done, either. If your paper cutting is in any way slowing down your productivity, you could argue you aren't meeting your paper cutting needs.

Your Safety Measures Are Out Of Date

Nobody should feel like their safety is at risk at the office.

Unfortunately, this is a more common issue than you might think, especially when it comes to sharp stationary equipment.

Check your manual paper cutter for finger guards, rust, and worn components which might break and injure your office workers.

Putting your cutter out to pasture doesn't mean replacing it with an electric one. There are plenty of great new manual cutter models, with new safety designs to put your staff's minds at ease.

The Construction Is Taking Some Wear

Of course, it's not just the safety features of your paper cutting equipment that can wear out over time.

If your guillotine or paper cutter has begun to wear out after years of daily use, you'll have two choices. Either have the components repaired, or replace them or the entire cutter. If you weigh up your repair costs, and the amount comes to more than replacing the whole manual paper cutter unit, you might need to buy a new device.

Using It Has Just Become Too Much Work

One of the biggest reasons for replacing any piece of manually-operated equipment is in the money it will save you, down the line.

When you operate a manual paper cutter, part of your cost to the company is in the man-hours spent operating each swing of the guillotine blade. Seeing as a person needs to be there, this can often lead to high operation costs, which can fall through to your clients.

In spite of the initial investment, an electric paper cutter can save you work hours and, by association, money.

You're Taking Too Much Time

It's a simple fact: there are times throughout the year when project workloads can get to be just a little too much, and businesses fall behind.

This is normal, but wasted opportunities in business can mean life and death. If you've identified an area where you could be cutting time out of your operation, however, why would you choose not to?

Reduce the amount of time you spend cutting paper with a newer model.

You're Losing Money Operating It Manually

As office equipment gets older, it tends to do its job less efficiently.

When it comes to paper cutters, that means frayed edges, uneven cuts, botched paper products, and, quite often, replacement paper and work.

If you analyze how much your business is spending on manual paper cutter issues, you're likely to find a number you're either okay with, or need to change. If you're spending more on fixing your mistakes than actually using your machine, you might need to replace your cutting device.

And remember: the average American office worker uses many thousands of sheets of paper in their time at the office, over a year. With so much waste going on, the question of pollution and the environment should also impact your decision to try and save paper through better cutting.

Your Standards Are Slipping

This is a short but important point: always pay attention to customer feedback when it comes to your paper quality.

If you get complaints about the quality of your cutting, you'll need to decide whether it's worth maintaining your current paper cutter.

Additional Features

Cutting your paper might be enough to make you buy into a new manual paper cutter.

Maybe you need more, though.

Newer model paper cutting units offer a variety of features and add-ons to make the entire process simpler. Adjustable blade depths and digital displays with backlights for poor lighting make up for the extra investment.

Automation

For some businesses, the root cause for changing from a manual paper cutter doesn't have to be complicated.

For some, just the prospect of automating their cutting process is enough.

Set a stack of papers to be cut to various sizes and in different numbers, and you can leave your cutter to do the work for you while you're away. Regardless of saving time and business costs, you'll be able to enjoy high-quality work without having to actually do it yourself.

And who doesn't love getting a few minutes out of their day back?

Space Limitations

Let's face facts: as technology becomes more refined, devices like paper cutters become smaller with every release.

In an office scenario where space is at a premium, changing from a manual paper cutter to something automated or even updated can be a breath of fresh air.

If your old paper cutter is taking up too much room, it might be time for a change.

Do Better, with a New Automatic or Manual Paper Cutter

Ultimately, the end goal of any business is to cut unnecessary costs, produce a quality product or service, and do better work.

In order to do that, you're going to need the right tools, especially in the print industry. With a high-quality paper cutter, whether manual or automatic, you can save time, produce better cuts, save resources, and take up less space.

More importantly, though, you'll be producing something that looks professional, every time.

Looking for high-end manual and automatic paper cutters? Check out some of our fantastic products, or get in touch with us, for more information.